Shotblasting

Sandblasting is virtually always an intermediate step in the process of finishing an item, and has the purpose of removing by erosion the most superficial layer of the part thanks to abrasion obtained by the jet of sand and air. This process is typically followed, in fact, by the painting or the application of protective substances.

The methods of shotblasting may be different, in particular it may be "wet" or "dry", however, in this industry the dry method is absolutely the most widespread and preferable, both for reasons related to corrosion, as for the quality of the final result. There is a further distinction between open cycle (conventional) and closed loop (aspired shotblasting): this second solution is the preferred one in our field, both for the aspiration of dust and because it allows the recovery of the exhausted abrasive material.

There are 4 different grades of shotblasting, related to the result of blasting to be obtained, from the most fine one, called "white metal" (Sa3, according to standard ISO8501-1), to the "blasting to near white metal" (Sa2,5), the "commercial blasting" (Sa2), to the "coarse sanding" (Sa1).

Another variable to consider in this process is the "blast profile", i.e. the degree of surface roughness to be obtained. The roughness depends directly on the particle size, the quality of the abrasive, and the initial conditions of the surface to be treated.

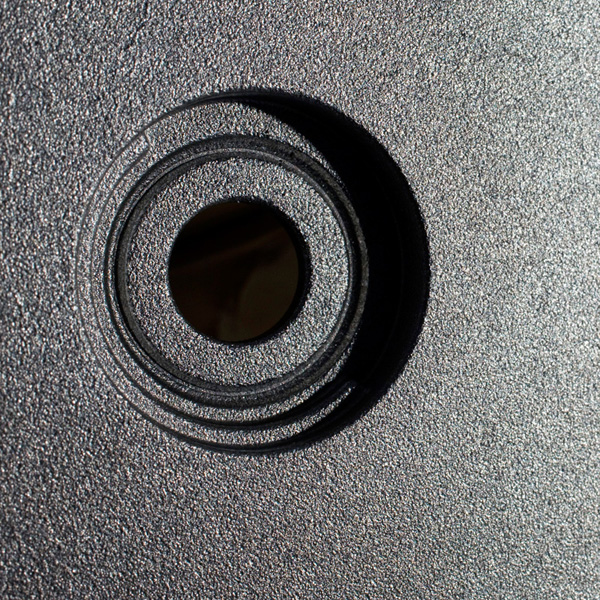

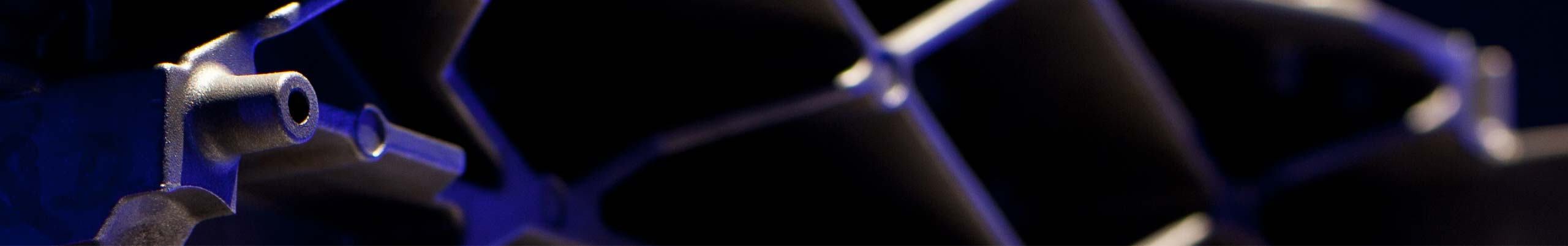

Here is an image a part shotblast at italpres.