Painting

Painting is typically the last of the finishing operations of die cast part. Often the customer requests the painting directly from the foundry that also takes care of all other finishing processes in order to optimize production efficiency.

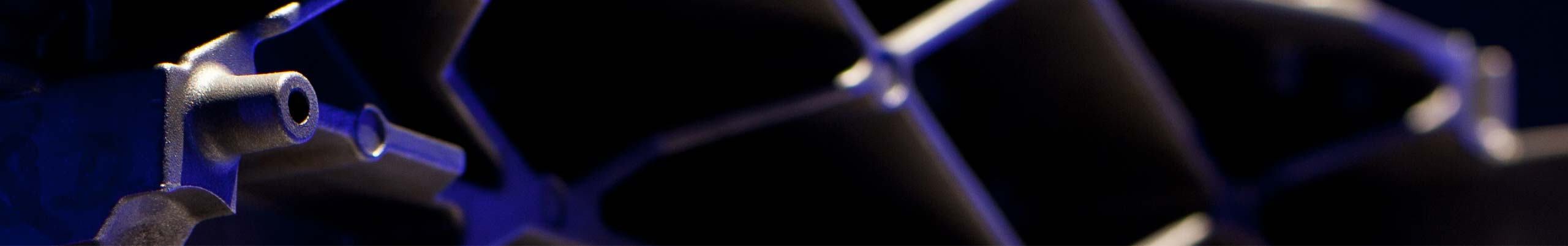

The metals painting proposed by italpres is technically powder coating, a surface coating process that can have both decorative and protective purposes against corrosion agents that could adversely affect its properties.

The process consists in covering first the die cast parts with the synthetic powder coating, then the parts are placed in a furnace in which, thanks to the temperature, the powder melts and then cures in a colored adherent film that coats all surfaces of the pieces.

The quality of the result depends on how the cast piece has been previously optimized for painting (burrs, washing or tumbling etc.). The powder coating is undoubtedly of better quality in terms of adherence, durability and resistance, also to mechanical stress, compared to liquid paint, but on the other hand is not comparable in terms of gloss of the paint.