From the developments on structural aluminum castings, a great opportunity for growth of the light alloy foundry system arises

The developments of knowledge in our country on structural light alloy diecast castings are extraordinarily interesting, we have had proof of this from many presentations at the METEF 2022 conferences, which are mentioned in other parts of the magazine.

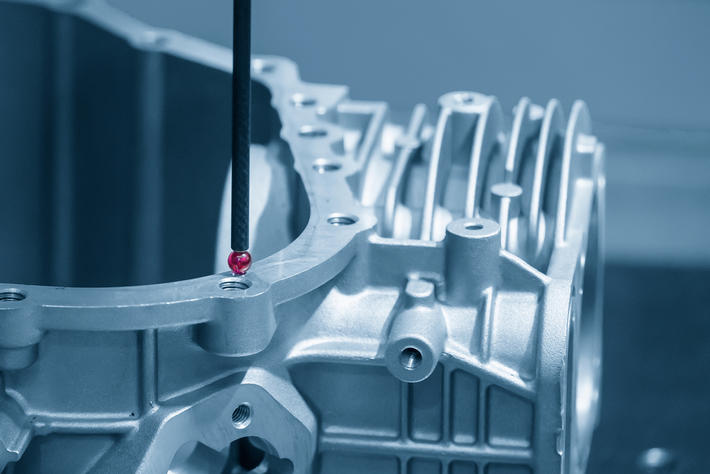

We are talking about products cast in aluminum alloys, even of large dimensions and with complicated geometries, with even very thin thicknesses, with high mechanical strength and toughness, resistance to corrosion, with good aptitude for weldability and surface treatments.

Structural diecastings: what they are

Like many materials, semi-products and applications of aluminum, structural jets have also won the attention of the market under the pressure of new needs for intelligent and sustainable lightening of means of transport, from automotive to aeronautics, naval and railways. , and will lead the way to an infinite number of new uses of aluminum castings in many segments, such as building and construction, mechanics, electrical engineering, wherever superior structural performance is required. An important step forward that translates into significant advantages such as:

- Lightening for designers with parts and components with superior mechanical characteristics and dimensional accuracy;

- The revolution of the design approach in particular in the car sector;

- Not only less weight but also less ancillary processing, thus reducing costs.

Great results, however, connected to a new paradigm of diecastings (multifunctional, larger, able to integrate more components) and to a new production complexity that must be adapted to the achievable quality and performance levels, and perhaps there is still a lot here to be done within the light metal foundry system in Italy and beyond, there is the doubt that part of the foundries in the sector, perhaps not attentive to the great changes underway, have not been able to benefit from the revolutionary progress in terms of alloys, new production and heat treatment processes, new design parameters of parts and components.

Looking at the industry segment, the ingredients are all there to promote and implement, starting from the national level, a common path of system growth, starting with the Universities and Metallurgical Research and Development Centers that have focused attention for years on the new "Aluminum Foundry" for structural castings. Among the many initiatives, we recall the HPDC International Conference launched in 2002 at the University of Padua and Vicenza as part of the activity of the AIM Metallurgy Association, recently in its seventh edition, and the School AQM of Provaglio di Iseo with the support of the University of Brescia. But we also have the constant study of aluminum in many university institutes, the diffusion of specific technical culture by Italian trade associations such as Amafond, Assofond, Centroal di Assomet, Aital, the creation of joint initiatives between companies, such as Foundry Star Alliance Team, promoted to ensure the optimization of diecastings produced with jig presses with over 9000 tons of closing force, constant and continuous communication support ensured by magazines and targeted initiatives such as METEF, the trade fair event that has years represents the voice of Italian aluminum in the world.

The dissemination of information and the transfer of knowledge on the specific segment of structural castings in light alloys are now fundamental aspects, which must include the involvement of all aluminum castings that have the ambition to improve and develop. By doing so, it will be possible to create an unmissable growth opportunity for our industry in the sector, which has always been a global reference point for machines, plants, processes, technologies and production of foundry parts and components.

Source: A&L Aluminum Alloys Pressure Diecasting Foundry Tecniques