Molds manufacturing

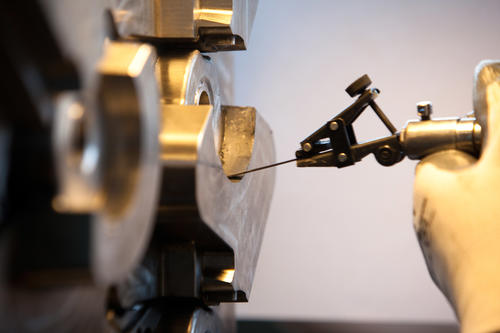

The decision to maintain an own, in-house molds department is not only a guarantee of promptness in solving tooling problems that may occur once they go into production, but also is a clear strategy aimed at having maximum possible control over the production process.

A choice that prevents wastes of time and misunderstandings, and offers the customer, at the same time, a single and reliable partner who takes charge of the entire process, and a more competitive price for equal technical service.

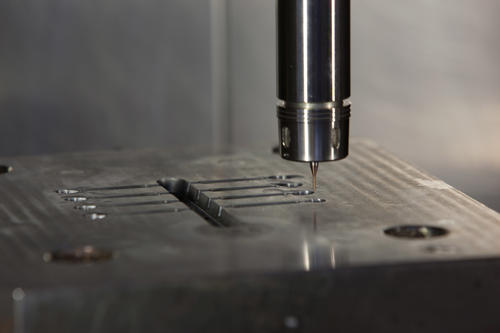

For this reason, from the beginning, italpres established a workshop for the manufacturing of die casting molds with advanced machinery, which are constantly upgraded or replaced on the basis of rapid technological innovations characterizing the sector.

italpres' molds manufacturing department benefits from dedicated technical staff, highly specialized and dedicated to continued training.

To date, italpres' molds manufacturing department built several thousand toolings, most of which technologically complex. Nevertheless, italpres just takes charge of producing the die cast component if the customer already has its own tooling, and remains at the customer's service to intervene, where necessary, on third-party molds as agreed upon.

More information about the Production process of a Die-casting Mold.

Molds and tooling built in-house since the establishment of italpres' toolshop

Specialized operators dedicated to developing, designing and manufacturing die casting molds

Square meters floorspace solely dedicated to manufacturing and servicing die casting molds