Fusion of die-cast aluminium products, also known as high pressure die casting or pressurised mould foundry, is a process developed in the United States during the mid-19th century where a molten metal or alloy is injected with high pressure into a metal mould. Once the injected metal has solidified, the metal mould is opened and the piece obtained is extracted.

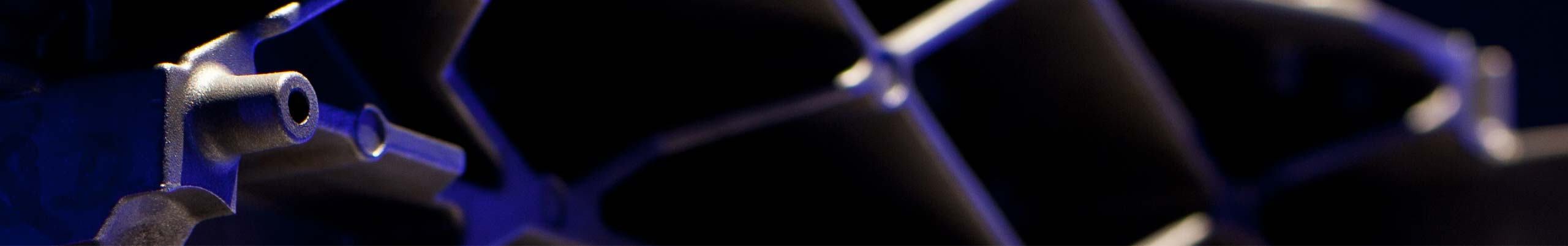

The steel mould for fusion of die-cast aluminium products consists of two shells to allow the extraction of the die-cast part. The materials used to make the various parts of the mould are always metals with higher melting points than the injected material, such as aluminium.

The injection pressure of the molten material may vary depending on the weight of the piece to be obtained, but also the type of melting material used. It is important that the pressure is kept constant throughout the melting process until the workpiece solidifies. In the meantime, hydraulic presses ensure perfect and complete closing of the mould: once the piece has solidified, the presses allow the two semi-moulds to open so that the die-cast part can be extracted.

The process of fusion of die-cast aluminium products is automatised and computerised and therefore lends itself to high productivity. The constant control of the casting process ensures the best possible quality of die-cast parts and maximises the production efficiency of their plants.

Thanks to the high technological and quality standards achieved today by equipment and machinery, the pieces produced by die casting ensure better minimum dimensional tolerances and surface finishes than other foundry processes.

Thanks to the modern die-casting systems of aluminium and zinc alloys with capacities ranging from 100 to 1400 tonnes, Italpres is able to manufacture high tech items with weights ranging from 4 grams to 15 kilos, either in small, medium or large scale production.