Italpres, a company specialised in the die-cast aluminium component mechanic processing, is the result of the dedication to work and business entrepreneurship of its founder Bruno Zani. The company was established in 1947 by Bruno Zani who started working as an engraver. Soon his entrepreneurship, technical knowledge and the moral and practical support of his wife, Flavia Ghidini, led to the first production of precision equipment and moulds.

At the beginning of the 1960s, Italpres bought its first water-pressure die-casting plant. Ever since it has gained international recognition in the area of die-cast aluminium component mechanic processing.

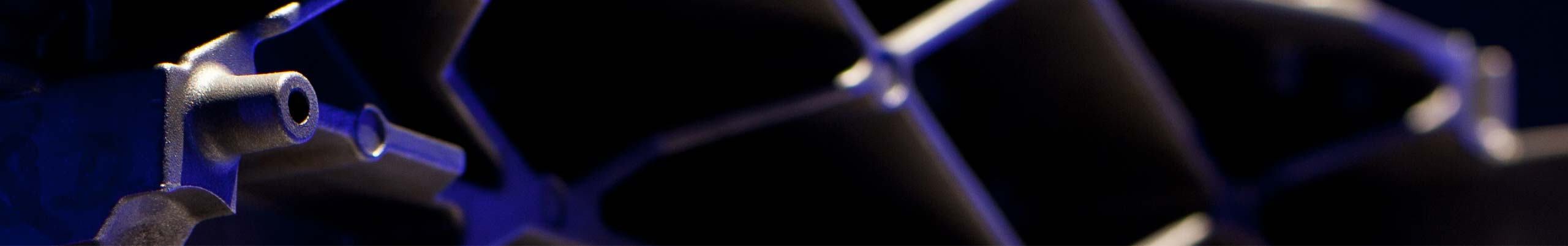

In 2017, the foundry celebrated its 70th anniversary of die casting of light alloy articles destined for all production sectors. For more than half a century, the company has been working in the design and production of moulds, and the die casting of aluminium and zinc alloys, producing articles for a wide range of sectors, including electronic parts, lighting, automotive, telecommunications, textile, oil-hydraulic, medical, hydraulic and many more.

A flexible mindset and competent staff have allowed the company specialised in the mechanical die-cast aluminium component mechanic processing to welcome over time the technological innovations of the industry and to broaden the customer portfolio, firstly throughout Europe, and now also the rest of the world.

The company's success at national and international levels is the result of a strategic decision made over the years: to ensure the customer with a single point of contact and responsible for the whole process of industrial production. Italpres deals with light alloy aluminium die casting, presenting itself as a reliable supplier and able to follow the entire production process, from co-engineering of the piece to the creation of the necessary equipment to produce it, from melting to finishing processes such as anodising, tumbling, grinding, machining, sanding, painting and assembling.