Italpres' department of die-cast aluminium component finishing is able to collect its customers' requests carrying out a series of treatments on the die-cast parts and also accepting requests for aesthetic finishes.

As a matter of facts, customers often prefer to commission these finishes directly to the manufacturer, both to speed up the process timing and to have a single referent and therefore not to have to follow each phase personally.

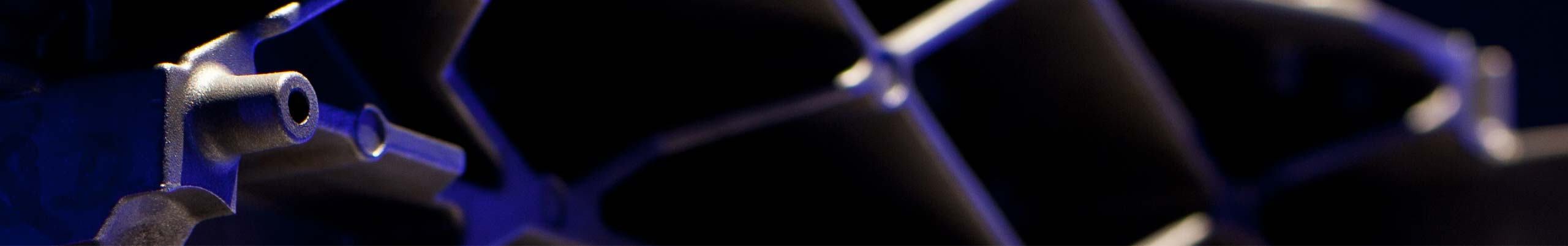

Among the die-cast aluminium component finishing, Italpres deals with:

- Anodising, an electrochemical process commonly used for aluminium through which a layer is created on the metal surface to protect it from corrosive agents;

- Tumbling, a finishing process often requested after the moulding or casting of aluminium products;

- Grinding, a finishing process in which an abrasive cloth is used to smooth the surfaces of the mould or die-cast article;

- Sandblasting, an intermediate process in the finishing process that uses erosion to remove the upper surface of the workpiece;

- Painting, typically the final finishing process of a die-cast aluminium article;

Finally, there are a number of mechanical processes that can be performed as die-cast aluminium component finishing. Usually these finishes provide the look of the piece that can not be created during the melting process and are mainly related to threads (screw housings), turnings (including knurling), polishing and special mechanical sanding, boring and reaming of holes (to ensure perfect cylindricality). Mechanical machining done on die-cast parts is usually oriented to the coupling of these with other parts, die-cast or not.