Lean Manufacturing in Foundries: Quality and Sustainability for Competition

Italian foundries face a complex challenge: international competition, increasingly stringent environmental regulations, high energy costs, and difficulty finding qualified labor. In this scenario, survival is not enough: they must grow, innovate, and differentiate themselves.

Three levers are proving decisive: Lean Manufacturing, green sustainability, and integrated quality. These are not abstract concepts, but practical tools that are already transforming small and medium-sized foundries, making them leaner, more resilient, and more competitive.

Many companies in the sector today find themselves at a crossroads. On the one hand, they must cope with rising costs and increasingly stringent constraints. On the other, some companies have already embarked on renewal paths, demonstrating that growth on all fronts is possible: increasing productivity, reducing waste, enhancing the value of the finished product, and reducing environmental impact.

Lean Production in the Foundry: Producing Better by Optimizing Resources

In recent years, some Italian foundries have embarked on a profound journey of simplification and continuous improvement, inspired by the five founding principles of Lean Manufacturing in foundries:

- Clearly define customer value: what is truly important to those who purchase the casting;

- Map the value stream: analyze all production activities and distinguish those that create value from those that generate waste;

- Create a continuous flow: ensure the material (liquid metal, equipment, cores) moves, minimizing downtime between production phases;

- Produce only on real demand (pull system): avoid overproduction and start production only when there is a concrete request;

- Continuous improvement (kaizen): seek small improvements every day to increase efficiency and quality.

Applying these principles in a foundry doesn't just mean "cutting costs," but rethinking the entire production process to make it more agile, effective, and competitive.

Faster, Leaner, Less Waste

In a medium-sized foundry, the introduction of process mapping allowed us to identify and eliminate bottlenecks, unnecessary waits, and superfluous steps. The results were tangible:

- A 20% reduction in lead times (the total time required to transform raw material into a finished part);

- A 15% increase in overall productivity;

- A better balance between available resources and the actual capacity of machines and operators.

Another key lever was standardization, i.e., the clear and shared definition of best working methods. This made it possible to:

- A 40% reduction in defects due to variability in working methods;

- Facilitated the onboarding and learning of new operators;

- Build a solid foundation for continuous and sustainable improvements.

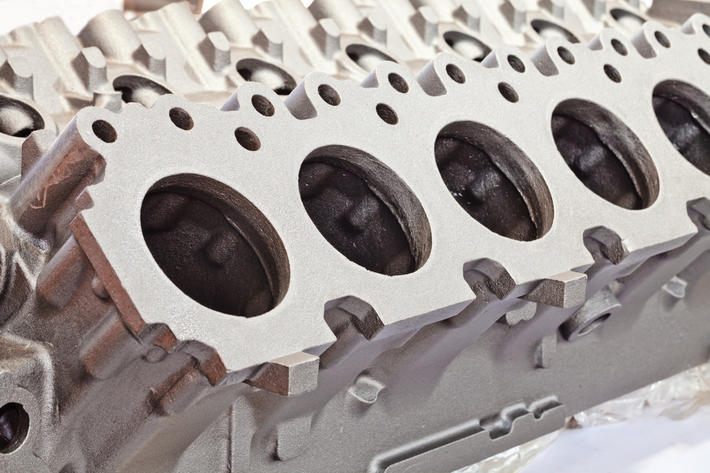

Technical interventions to optimize die-casting processes

Some specific Lean Production tools in the foundry have also brought tangible results:

- SMED (Single-Minute Exchange of Die): a technique for drastically reducing the time required to change equipment. Applying it resulted in an average 30% reduction in setup times, making it possible to produce smaller batches and better respond to urgent or variable orders.

- TPM (Total Productive Maintenance): this isn't just about "performing maintenance," but involving the entire team to prevent breakdowns and improve equipment efficiency. In some foundries, this has led to a 25% reduction in unplanned downtime.

Every waste eliminated, every phase simplified, every standard rule applied is a concrete step towards a more agile, stable, and competitive foundry. When the production flow is continuous, standardized, and driven by real customer demand, quality and environmental sustainability also begin to improve naturally.

Sustainability: Less environmental impact and greater production efficiency

In an increasingly sensitive environment for climate, the environment, and sustainable supply chains, the foundry industry is also moving forward. Not out of fashion or obligation, but because sustainable solutions work: they reduce costs, improve efficiency, and strengthen the company's reputation among increasingly demanding customers.

In many Italian foundries, sustainability strategies are no longer just regulatory compliance, but competitiveness levers. The concept of "green manufacturing"—production with low environmental impact—is finding concrete application in various areas: furnaces, sand, compressed air, materials, and even energy supply.

A more sustainable foundry is also more competitive

A concrete example involves the installation of a heat recovery system from melting furnaces, which has led to:

- 25% reduction in overall annual energy consumption;

- 30% reduction in CO₂ emissions compared to the previous average;

- Estimated savings of over €90,000/year on energy bills alone.

Accessible technologies like this do not require new equipment or extraordinary resources: it often involves modifying, integrating, and recovering energy or materials where they were previously lost.

Less environmental impact, greater production efficiency

Other real-world examples demonstrate the potential of operational sustainability:

- The introduction of advanced filtration and sand regeneration systems has led to a 35% reduction in waste materials;

- The use of recycled metal materials (selected scrap) has reduced the cost of raw materials by up to 20%;

- Some foundries have begun partial conversion to renewable sources, with photovoltaic systems now covering up to 18% of their electricity needs.

These numbers, regularly updated by observers like Assofond, speak clearly: a more sustainable foundry is more stable, more resilient, and closer to the customer.

Affordable sustainable technologies

When we talk about sustainability in foundries, we often think of complex and expensive projects. In reality, many technologies already available offer concrete, accessible, and measurable results:

- Emissions and solid waste: several Italian plants have introduced advanced filtration and sand regeneration systems, reducing waste disposal by up to 35%.

- Raw materials: the increased use of selected scrap and recycled materials has allowed us to reduce charge costs by up to 20% without compromising the quality of the castings.

- Energy: In addition to photovoltaic systems and heat recovery from furnaces, improvements such as improved insulation, optimized compressors, and streamlined internal logistics are being implemented, leading to savings of more than 8% annually.

Sustainability in the foundry isn't a long-term project, but a set of practical actions that can be implemented immediately, often with limited investments and rapid returns. It's no longer an ethical or political choice: it's an industrial strategy that works.

Integrated Quality: The Foundation for the Success of Italian Foundries

In a complex and competitive industry like the foundry industry, quality isn't just a badge of honor: it's a culture, an invisible yet fundamental infrastructure. Integrated Management Systems—structured according to standards such as ISO 9001, ISO 14001, and ISO 45001—now represent the connective tissue that enables the effective integration of Lean Manufacturing and environmental sustainability.

These certifications, when viewed not as a bureaucratic constraint but as strategic tools, allow companies to anticipate problems, improve processes, engage staff, and create value for the end customer.

The Evolution of ISO 9001:2026

A major change is coming: the new version of ISO 9001, expected in 2026, will not be a simple technical update. Previews indicate a strengthening of some themes already present in the 2015 version:

- Greater focus on change management and operational resilience;

- Structural integration of concepts such as sustainability, digitalization, and knowledge management;

- Even closer alignment with the United Nations SDGs (Sustainable Development Goals).

Companies that are already working on these fronts today—continuous improvement, reducing environmental impact, digitalizing processes, and engaging people—will have an advantage in adapting to the future norm.

Digital Quality Control: The Smart Era

In some Italian foundries, the introduction of digital quality control systems—equipped with advanced sensors, predictive systems, and intelligent algorithms—has marked a turning point: a 40% reduction in scrap, thanks to real-time monitoring of critical parameters; a 25% improvement in the dimensional accuracy of castings, reducing the need for rework; and a shift from a reactive model to a predictive-preventative approach, capable of flagging deviations before they become non-conformities.

The benefits are not only qualitative, but also environmental and economic: less scrap means less material to remelt, less energy consumed, and less waste to manage. In short, quality and sustainability go hand in hand.

Product development and reduced time-to-market

More and more customers are demanding rapid turnarounds and precise responses even during the quotation phase. With a structured approach based on APQP, integrated simulations, and visual management of Requests for Quotation (RFQ), customer response times are reduced by up to 30–40%, while simultaneously improving the quality of offers and the likelihood of winning orders.

The process unfolds across two critical phases. In the quotation phase, standardizing technical inputs through verification checklists allows for the preemptive risk analysis of each commercial proposal. The use of visual boards and digital kanbans allows for constant monitoring of progress, while early involvement of production and quality control ensures that offers are realistic and feasible from the outset.

Once the offer is converted into an order, the industrialization and sampling phase begins. The kick-off meeting and contract review allow for shared objectives and constraints across all company functions, creating a solid foundation for the project. Analysis, design, and simulations are supported by consolidated checklists that reduce errors and rework. Progress is visible through a kanban board, facilitating coordination between the technical and production departments with clear data and responsibilities. Sampling and operational testing ensure process repeatability and quality, while final testing and project closure always include systematic data collection and updating standards through lessons learned.

With this integrated approach, the foundry not only responds more quickly to the market, but also dramatically reduces industrialization times, increasing delivery reliability and customer trust.

The Winning Trio for Italian Foundries

Lean Manufacturing, sustainability, and integrated quality are not slogans, but a concrete method that can transform Italian foundries, even small and medium-sized ones. Perfect projects or colossal investments aren't necessary: change starts with a first step, a small sign of attention, a tidy workstation, a clearly visible indicator, an observation made at the right time.

Every company can start today by choosing a critical area to address and embarking on a guided path. The benefits are tangible and progressive:

- Less waste and rework;

- Lower consumption and hidden costs;

- Greater productivity, stability, and pride in one's work.

In a context where regulations are evolving and customers are increasingly demanding more, those who can monitor their processes, engage their people, and integrate method, quality, and sustainability through the optimization of die-casting processes and daily production will not only survive, but thrive.

Source: In Fonderia – Il magazine dell’industria fusoria italiana