Aluminum in Electric Mobility: Sustainable Innovation for Next-Generation Battery Containers

The transformation of contemporary mobility is completely redefining the automotive industry's paradigms, placing the circular economy and sustainability at the center of development strategies to achieve the European goal of carbon neutrality by 2050. Achieving this ambitious target requires a synergistic and integrated approach, from raw material selection to recycling processes, through the design of products conceived from the outset for effective reuse.

True sustainability in aluminum for electric mobility can only be achieved through consistent and cross-cutting activities throughout the entire low-emission vehicle production chain. The product concepts developed in this area adhere to the 4R principles (reduce, reuse, regenerate, recycle) right from the raw material selection stage, representing a model of excellence for the industry of the future.

The Revolutionary Potential of Secondary Aluminum in Automotive

Secondary aluminum alloys represent a technological revolution in the automotive sector, offering a carbon footprint up to 20 times lower than primary aluminum, resulting in significant benefits in terms of CO2 emissions. These alloys also offer virtually infinite recycling potential, maintaining their performance characteristics through multiple reuse cycles.

The mechanical and physical properties of secondary aluminum in automotive applications can meet high performance objectives through optimized product design. Through targeted design that leverages the specific thermostructural characteristics of each alloy, even secondary alloys—despite sometimes having inferior mechanical properties compared to primary alloys—can achieve excellent performance in electric mobility applications.

When disassembly is considered from the initial design phases, selective reuse and environmentally friendly recycling of components is ensured, creating a virtuous cycle of sustainability that represents the future of the automotive industry.

Research and Development: Scientific Foundations for Innovation

Scientific literature has shown growing interest in the study of aluminum-silicon foundry alloys derived from end-of-life automotive components. Research has focused in particular on AlSi7 and AlSi9Cu3 alloys, highlighting the potential of these materials for advanced applications. Foundries are constantly evaluating the possibility of recycling process waste and reintroducing it into production, optimizing the overall efficiency of the production cycle.

By considering secondary aluminum alloys from the early concept design stages in the development of easily disassembled battery modules, the reuse and recycling of both aluminum battery cases and lithium-ion cells takes on a fundamental strategic importance for the future of sustainable mobility.

Sustainable Design: The 4R Approach

The concepts of Reduce, Reuse, Recover, and Recycle form the foundation of a revolutionary eco-sustainable approach. When adopted from the product concept stage and subsequently in design and industrialization, they ensure a circular economy of vital importance for contemporary Europe. European Union countries are over 80% dependent on imports of critical raw materials, particularly critical for all materials used in lithium-ion batteries.

In this context, designing for easy disassembly significantly contributes to ensuring the selective reuse of high-value components, such as lithium-ion cells. The selective approach to material separation allows for secondary use of both cells and battery components, making a decisive contribution to a sustainable circular economy.

Technical Development of Aluminum Battery Cases

Innovative Materials and Methodologies

The production of battery cases through High Pressure Die Casting (HPDC) offers significant advantages in terms of production efficiency and final product quality. The materials under study, based on the Al-Si10 and AlSi9Cu3 systems, were subjected to comprehensive corrosion resistance assessments through salt spray tests and mechanical strength assessments through crash tests and tests on case sections taken from the walls and bottom.

Design for Easy Assembly and Disassembly

An in-depth benchmark analysis identified the materials and assembly technologies for battery modules currently available on the market, highlighting their suitability and ease of recycling. In most current cases, the module is made by welding and gluing the elements together, making it extremely difficult to access the lithium-ion cells and separate them from the case without destroying the module.

The innovative design proposal called BM-Basic Module was developed following the 4Rs perspective and includes only two elements: a die-cast aluminum container and a lid, which can be made of flame-retardant technopolymer or also of aluminum alloy, depending on the applications and conditions of use of the battery.

Material Selection and Process Optimization

To ensure the expected performance in terms of impact resistance, vibration resistance, corrosion resistance, and weight reduction, particular attention was paid to the choice of aluminum alloy and its corresponding LCA contribution in terms of CO2 equivalents. Excluding primary alloys due to their high environmental impact (CO2 equivalent contribution approximately 20 times higher than secondary alloys), research focused on two innovative secondary alloys:

- SilvAl10: a variant of the AlSi10MgMn family obtained with 90% recycled material;

- RESAL: a variant of the AlSi9Cu family obtained with 100% furnace-ready recycled material.

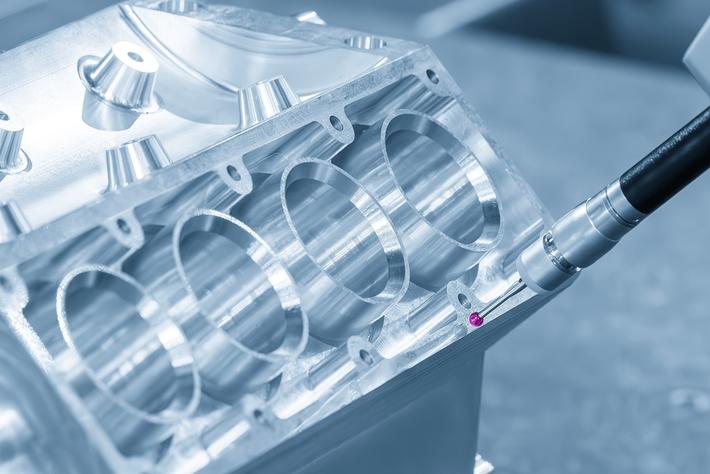

To ensure proper functionality of the container-battery system, including proper insertion of the lithium-ion cells and effective heat exchange to ensure long-term durability, the container design required optimization of the die casting process combined with mold design capable of producing products with minimum wall thicknesses of up to 1.5 mm, a 0.5° draft angle, and flatness of the lower wall in contact with the cell cooling systems.

To ensure proper mold filling and prevent the formation of cold joints or gaps, particularly likely with thin walls, the casting layout was defined using an innovative virtual filling simulation analysis methodology. Using advanced image analysis software, the areas of the molten metal front with temperatures below the solidus temperature were calculated at specific moments during metal injection, allowing comparison between alternative casting system geometries.

Technical Characterization and Performance of the BM-Basic Module

Strength and Durability Test Results

Using a 1350-ton press equipped with appropriate temperature control, lubrication, and vacuum systems, significant batches of BM-Basic Modules were produced in SilvAl10 and RESAL alloys. Some defects, still detectable after process development and highlighted by CT scan analysis, did not affect the results of the leak testing of the castings, which were subsequently prepared for lateral crash testing for both alloys.

Under lateral loading conditions, the SilvAl10 alloy met the requirements without failure, while the brittleness of the AlSi9Cu3 alloy did not allow it to pass the lateral crash test. Another product requirement met exclusively by the SilvAl10 alloy is corrosion resistance, as the high copper content of AlSi9Cu3 is one of the main causes of corrosion.

In-depth mechanical characterization

Three-point bending tests were performed on container portions measuring 60 mm in length, 15 mm in width, and varying in thickness depending on the sample area. On the bottom of the box, an average maximum force value exceeding 500 MPa was observed, with an average deviation of 6.3 mm. With the T5 heat treatment, an increase of approximately 100 MPa in Rp0.2 was observed, an increase of approximately 80 MPa in maximum force, and a reduction of approximately 2 mm in maximum deflection.

On the walls, different values were observed between the casting wall and the second wall, while the T5 treatment resulted in greater uniformity of the values obtained, significantly reducing the gap previously observed.

Life Cycle Assessment and Environmental Benefits

Integrated Responses to the 4Rs

The BM-Basic Module provides a comprehensive response to each R of the 4R methodology:

- Reduce: Uses 2 elements instead of 3 or 4 of the alternative solutions;

- Reuse: The lithium-ion cells removed from the container are maintainable and reusable for other applications;

- Recover: The container and its lid can be recovered for a new module;

- Recycle: The container can be recycled in the secondary aluminum stream, and the cells in the dedicated stream.

Quantified Environmental Impact

In terms of LCA contribution - CO2 equivalent, the BM-Basic Module version with a secondary aluminum sheet lid offers a significant reduction when considering both the raw materials used and the transformation and assembly processes. The reduction becomes even more notable when considering the possible reuse of lithium-ion cells for other applications, an alternative not practicable with alternative products without destructive recycling of the modules and cells contained within.

Future Prospects for Aluminum in Electric Mobility

This work has highlighted how secondary alloys represent a valid alternative for the development of components for electric mobility. Knowing the mechanical and physical characteristics of these materials, appropriate die casting design has enabled the creation of aluminum battery containers capable of ensuring high performance in both crash testing and corrosion and bending tests.

New product concepts that take the 4Rs into account offer significant contributions to CO2 reduction, demonstrating how technological innovation and environmental sustainability can go hand in hand towards a truly sustainable future of mobility. The integration of secondary aluminum into automotive battery systems represents a fundamental step towards the creation of a fully circular and carbon-neutral automotive industry.

Source: In Fonderia – Il magazine dell’industria fusoria italiana