Artificial intelligence in die casting and metal industry

Artificial intelligence in the metal industry is rapidly transforming the die casting and metalworking sector, offering new opportunities to optimize production processes, improve efficiency and increase the competitiveness of companies. This technology, now increasingly accessible, is becoming a strategic factor for companies that want to remain competitive in a global market characterized by increasingly complex challenges.

Challenges and opportunities of digital transformation

The digitalization of the metals industry is accelerating significantly, driven by recent global challenges that have disrupted traditional production paradigms. As highlighted during a recent conference organized by Assofermet (the association representing 450 companies in the steel, ferrous scrap, non-ferrous metals and hardware sectors), global investments in this field show substantial differences: "In 2023, the United States allocated 67 billion dollars to artificial intelligence, China 8 billion, and Europe distributed a similar investment over a five-year period", underlined Cinzia Vezzosi, President of the association.

Despite the ethical challenges still open, the metallurgical industry is progressively embracing this technology, transforming it from a potential obstacle into a strategic resource. If well implemented, artificial intelligence can significantly increase productivity and optimize business processes, strengthening the competitiveness of companies in the sector.

The AI Act and its impact on the metallurgical industry

The European regulatory framework on artificial intelligence represents a fundamental element for the future development of the sector. The AI Act, the European regulation dedicated to artificial intelligence, will have a significant impact on the metallurgical industry in the coming years, defining the parameters within which companies will be able to implement these technologies.

According to Brando Benifei, MEP and rapporteur of the AI Act, "incentives, including fiscal ones, investments and clear rules are needed to continue to support the implementation of AI by companies." Monitoring the application of the Regulation will be crucial to ensure that artificial intelligence represents "a real opportunity to protect citizens and businesses."

The European approach to AI regulation differs substantially from that of other global powers: "Our idea of development puts consumer protection rules at the center and is different from that proposed by China and the United States," Benifei highlighted. This approach aims to create an effective competitive environment, in line with what was stated in Mario Draghi's competitiveness report, while ensuring the protection of fundamental rights.

Concrete benefits of AI for die casting companies

The benefits of AI for die casting companies are already tangible and measurable. Concrete implementation experiences in the sector show significant results: the application of artificial intelligence systems has increased the efficiency and productivity of certain business processes by 57%, as reported by experts in the industrial cybersecurity sector.

Even relatively simple applications based on AI have led to considerable reductions in execution times, going from 12 to 7 hours for certain processes and generating a saving of 1,400 hours per year. These data highlight how the adoption of intelligent technologies does not necessarily require mammoth investments to obtain significant returns.

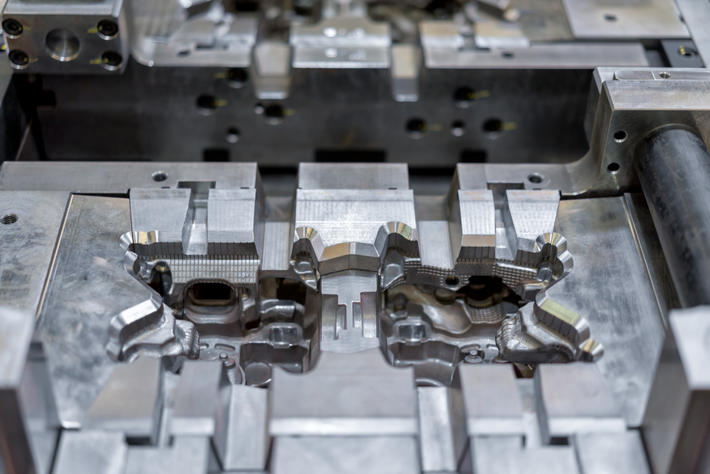

Practical Applications in Metal Manufacturing

Artificial intelligence in the metals industry has many practical applications that are transforming traditional manufacturing processes:

- Predictive maintenance: Advanced algorithms analyze machine data to predict potential failures before they occur, reducing downtime and maintenance costs.

- Process optimization: AI optimizes process parameters such as temperature, pressure, and cycle times, improving product quality and reducing waste.

- Automated quality control: Machine vision systems inspect components in real time, identifying defects with greater accuracy than traditional methods.

- Energy efficiency: Intelligent algorithms monitor and optimize energy consumption, reducing operating costs and the environmental footprint.

- Advanced automation: Cobots (collaborative robots) and automated systems driven by AI increase productivity and improve operator safety.

Future prospects of digitalization in the metals industry

The digitalization of the metals industry is set to accelerate in the coming years, with artificial intelligence playing an increasingly central role. Companies in the metals sector, including those specialized in die casting, are gradually adopting AI-based solutions to address complex challenges and seize new market opportunities.

These technologies not only improve operational efficiency and product quality, but also contribute to environmental sustainability goals by reducing waste and optimizing the use of resources. The implementation of AI solutions allows to minimize energy consumption, optimize the use of raw materials and reduce CO2 emissions, thus aligning business strategies with the decarbonization goals of the industrial sector.

With the implementation of the European regulatory framework, metals companies will have to adapt to the new rules, but they will also benefit from a more structured and predictable environment for the development of innovative solutions. The impact of the AI Act on the metals industry will likely translate into increased investments in transparent, ethical and compliant systems, while creating opportunities for new business models and value-added services.

Companies that can effectively integrate AI into their decision-making and production processes will have a significant competitive advantage. For this reason, investing in digital skills and adopting advanced technologies are key factors to remain competitive in a global market increasingly driven by technological innovation and the digitalization of the metals industry.

Companies that are able to effectively integrate AI into their decision-making and production processes will have a significant competitive advantage. For this reason, investing in digital skills and adopting advanced technologies are key factors to remain competitive in a global market increasingly driven by technological innovation and the digitalization of the metals industry.

The experiences already documented demonstrate that even small and medium-sized enterprises can significantly benefit from the adoption of these technologies, with rapid and measurable returns on investment. The challenge for the future will therefore be to democratize access to these solutions, making the benefits of AI for die-casting companies accessible to an ever-increasing number of companies, regardless of their size.

Source: A&L Aluminium Alloys Pressure Diecasting Foundry Techniques