Over the years, the company has distinguished itself by promptly resolving any problems that might affect the tooling once it has reached the die-casting stage.

This guarantee is given by the decisive choice to have its own internal department for the production of aluminium die-casting moulds.

This choice by italpres represents a production strategy aimed at gaining control of the entire production process, thus avoiding wasted time and misunderstandings, and offering the customer a single, reliable partner at a more competitive price, given the same technologies used.

italpres, since its origins more than 74 years ago, has created a department for the production of aluminium die-casting moulds equipped with state-of-the-art machinery, which is constantly updated or replaced on the basis of disruptive technological innovations.

Machines are nothing without people

The production department is staffed by dedicated and highly specialised technical personnel, nurtured by continuous training and a passion for their work.

In addition, there is a wide range of equipment available for the production of moulds, many of which are technologically superior and particularly complex.

All this without forgetting that italpres can work on the die-casting of an article if the customer already has the relevant equipment, as well as offering the availability to work on third party equipment if necessary.

What is needed for the production of quality dies?

We have to remember that the stages of metal die-casting are delicate and must follow very strict standards.

The processing is carried out using a specific workstation, consisting of various parts, such as the injection system, which is responsible for inserting the molten metal into the metal mould.

Not forgetting the channeling phase, which is by all accounts one of the most delicate steps in the entire procedure. It must respect very precise parameters of pressure, time and speed.

The materials used and the mould

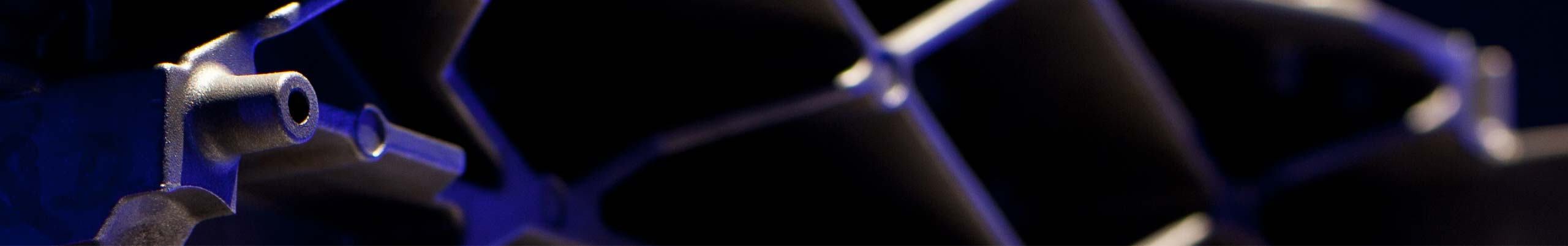

The material used to make the moulds is steel, which has a higher melting point than the injected material, aluminium. Some parts of the mould can be made of different types of steel, to facilitate certain processes useful for the production of the mould itself.

The production of aluminium die-casting moulds is carried out directly in the italpres plant in Lumezzane, where there is a technological laboratory equipped with machinery that allows very high precision machining (in the order of hundredths of a millimetre) based on technologies such as EDM.