Metal die casting is an ancient technique, dating back as far as 1800, first developed and perfected in the United States.

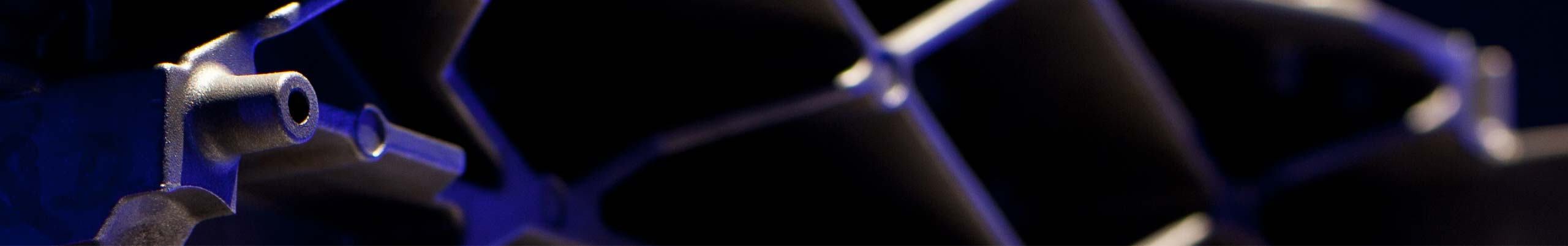

Also known as die-casting, or pressure die-casting, die-casting is a special foundry process in which molten metal is injected at high pressure into a metal mould.

Aluminium die-casting makes it possible to obtain metal parts quickly and with a good degree of finish. This has certain advantages that cannot be achieved by casting alone. There is a very fast and perfect filling of the mould cavity and also an excellent crystalline finish.

This extraordinary technique began to make its way into Italian industrial production thanks to the dedication and resourcefulness of Bruno Zani, founder of italpres in 1947.

In the early 1960s, italpres installed the first hydraulic water die-casting system, representing a crucial step for aluminium die-casting.

International companies began to better understand how essential this technique was in the development and production of tools, but above all in the production of high-quality die-cast parts.

The benefits of aluminium die-casting on the end product

The aluminium die-casting process offers numerous advantages on the end products, such as:

- The excellent and incredible surface finish

- Dimensional tolerances due to the tight molecular structure, free of micro-cracks

- Good tensile strength and a high coefficient of elastic modulus

- The reduction of porosity and impurities

- Accurate thicknesses, even thin ones, in some cases less than 1.5 mm

- Air and liquid pressure resistance

- The low cost of the raw material

- Longer service life compared to other processes

- The wide range of choice of alloys with different mechanical characteristics

- The possibility of incorporating metal inserts

- The possibility of obtaining products with complex shapes

- The wide range of applications in various sectors

The advantages of aluminium die-casting in the production cycle

Die-casting is even more advantageous because it guarantees

- Mass production of large quantities of objects thanks to a single mould

- Reduction in the cycle time of the casting process

- The economy of the equipment in relation to the potential production volume

- The reduction of chemical reactions leading to the cancellation of metallisation.

The love affair between italpres and die-cast aluminium

The company's own foundry celebrated its 74th anniversary in 2021 in the die-casting of light metal alloys for all production sectors, making it the longest-lived foundry in the sector.

italpres machinery guarantees the best possible quality of die-cast metals, thanks to a process of automation and computerisation that allows constant control of the casting process.

In addition, this technology guarantees an extraordinary quality of the parts being die-cast.

The italpres company produces articles for a wide range of industries, including electronic components, lighting, automotive, telecommunications, textiles, hydraulics, medical and many others.

A flexible and particularly inquisitive attitude, combined with a competent staff, has been the key to keeping pace with technological innovations in the sector, expanding the customer base first in Europe and then in the rest of the world.

The company's success is the result of a strategy that has been constantly refined over the years, namely that of guaranteeing the customer a single, competent partner for the entire industrial production process.

italpres' mission is to produce special die-cast aluminium alloys, offering itself as a reliable supplier able to follow every phase, from the co-engineering of the part to the construction of the production plants, from casting to anodising, finishing, vibratory finishing, grinding, machining, sandblasting, painting and assembly.

die-casting is still the most widely used technology today, not only because of all the advantages it brings to the end product and the production process, but also because it is the most cost-effective and high-performance technique for producing aluminium alloy objects.