The importance of making molds for the die casting of aluminum and zamak alloys

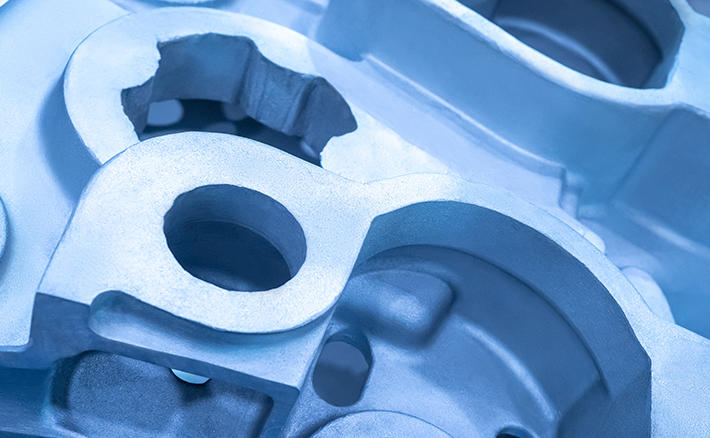

In the die casting process, there are, among others, two aspects on which to focus attention: the construction of the molds and the type of alloy to be cast in the molds. The molds are fundamental because they give shape to the finished piece: if they are well made, the final product will be too. This is why italpres has decided to equip itself with an internal mold department to have security and control over their manufacture: delegating to the outside means relying on processing that is out of internal control, with all the necessary risks.

The molds are the necessary condition for quality die-cast parts

The realization of molds for die casting of aluminum and zamak alloys must be a guarantee on the process and on the quality of the work. In other words, it is the necessary condition for creating excellent finished pieces. Once made and approved, the molds are used for hundreds or thousands of die casting cycles. Even the best aluminum and zamak alloys, therefore, depend on the quality of the mold: if it is defective, the entire lot of production will be compromised.

The qualities of zamak in the die casting process

We have mentioned zamak, in addition to aluminum, even if it is not the favorite material of italpres because it is a possibility for die casting which guarantees many advantages: reduction of production costs, excellent mechanical properties and finishes. Zamak, also known as Zamak (Z-Zinc, A-Aluminum, MA-Magnesium, K-Copper in German), is an alloy composed mainly of high purity zinc, mixed however with small percentages of aluminum, in addition to those of magnesium and copper. The contribution of these elements gives hardness and resistance to zinc, which otherwise would be fragile and not very resistant. Zamak is therefore not an aluminum alloy, it is zinc, but it contains and a small percentage of the material daily treated by italpres. Aluminum, in fact. And above all it is mainly treated with die casting: it is the most common method for processing zinc alloys.